Removing and Isolating Fridge Components for Recycling

The process of recycling a fridge, freezer or an air-conditioning unit is to first of all extract all the hazardous refrigerant from the system without losing any.

37.65 million domestic refrigerator appliances and counting

If we take the figure of 37.65 million domestic appliances in the 2019 audit with a shelf life of 12.5 years and if we double that number as a very crude estimate to take into account all the fridges and freezers in all the shops, supermarkets, food manufacturers, laboratories, restaurants, bars, cafes,(not to mention ice machines) and then add in all the domestic and commercial air-conditioning units and round it up to 76 million.

Vehicle Air conditioning Systems

We won't consider the number of air conditioned cars, vans and trucks into the equation or the fugitive emissions, the unintentional release (leaks) from the air-con units in the event of a collision.

That is a lot of harmful material and that is just the UK, a relatively temperate climate.

The recycling of refrigeration equipment adopts a dual role, one of economy and the other of a defensive / preservation activity.

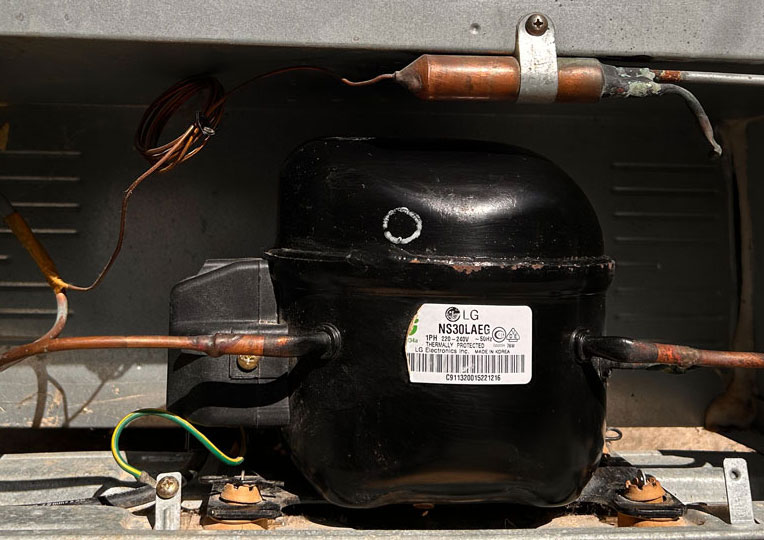

Degassing Plants isolate and capture hazardous refrigeration gasses and materials

Fridges go to degassing recycling plants (as opposed to metal recycling plants) that can process fridges to WEEE standards including those that have pentane in fridges which is a blowing agent used in the insulating foam as an alternative to CFCs.

Refrigerator Recycling Process - How are fridges and freezers made safe?

Initially, glass plates, mercury switches, and capacitors are removed.

The refrigerant gases are removed.